aluminum rubber seals

Aluminum rubber seals, also known as aluminum and rubber composite seals or aluminum edge trim seals, are sealing components designed for various applications where a combination of the rigidity of aluminum and the flexibility of rubber is required. These seals typically consist of a flexible rubber or elastomeric section bonded or encapsulated within an aluminum channel or carrier. This combination of materials allows for effective sealing, protection, and often serves aesthetic or structural purposes. Here are some key aspects and common uses of aluminum rubber seals:

**Key Features and Functions:**

1. **Sealing:** Aluminum rubber seals are primarily designed for sealing purposes. The rubber or elastomeric part of the seal provides a flexible, compressible barrier that prevents the infiltration of liquids, gases, dust, or contaminants between two surfaces.

2. **Weather Resistance:** These seals are often used in outdoor applications where they provide protection against weather elements, including rain, UV radiation, and temperature fluctuations.

3. **Shock Absorption:** The rubber component of the seal can absorb shocks and vibrations, which is particularly useful in applications where impact resistance is required.

4. **Noise Reduction:** Aluminum rubber seals can help reduce noise transmission by sealing gaps and isolating vibrations.

5. **Durability:** The combination of aluminum and rubber provides a balance between structural durability and flexibility, making these seals long-lasting and resilient.

**Common Uses of Aluminum Rubber Seals:**

1. **Doors and Windows:** These seals are used in doors and windows to provide weatherproofing, sound insulation, and airtight sealing. They are common in residential, commercial, and industrial buildings.

2. **Automotive:** Aluminum rubber seals are employed in vehicles for sealing doors, windows, trunks, and sunroofs. They help keep the interior of the vehicle dry and quiet.

3. **Containers and Cabinets:** These seals are used in the manufacturing of containers, cabinets, and enclosures, where they provide sealing against moisture, dust, and environmental contaminants.

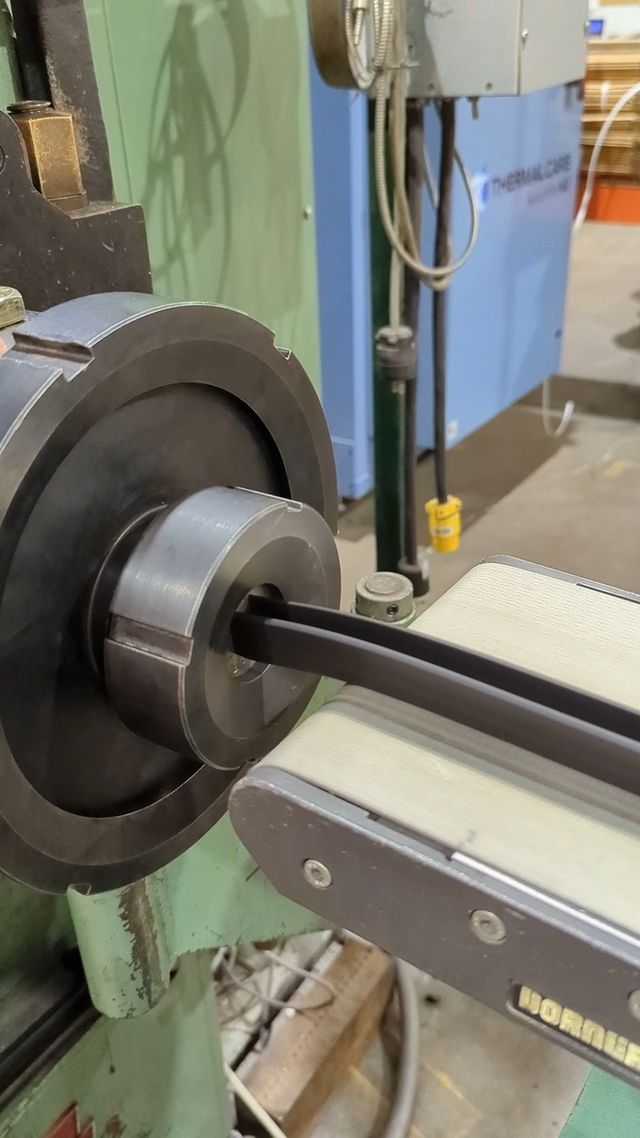

4. **Industrial Machinery:** Aluminum rubber seals can be found in industrial equipment, such as conveyor systems, to protect moving parts, reduce noise, and maintain hygiene in food processing.

5. **Marine Applications:** In the marine industry, these seals are used to create watertight compartments on boats and ships.

6. **Aerospace:** Aerospace applications use aluminum rubber seals to seal access doors, windows, and hatches on aircraft.

7. **RVs and Campers:** Recreational vehicles (RVs) and campers utilize these seals to ensure a tight seal on doors, windows, and compartments.

8. **Furniture:** In the manufacture of furniture, aluminum rubber seals can be used for decorative and functional purposes, such as sealing cabinet doors or providing a finished edge to a table or countertop.

9. **Electrical Enclosures:** They are used to seal electrical enclosures and cabinets to protect sensitive components from environmental factors.

Proper selection and installation of aluminum rubber seals are essential to ensure that they meet the specific sealing and protection requirements of a given application. These seals come in various profiles and sizes to accommodate different design and performance needs.

Yorumlar

Yorum Gönder